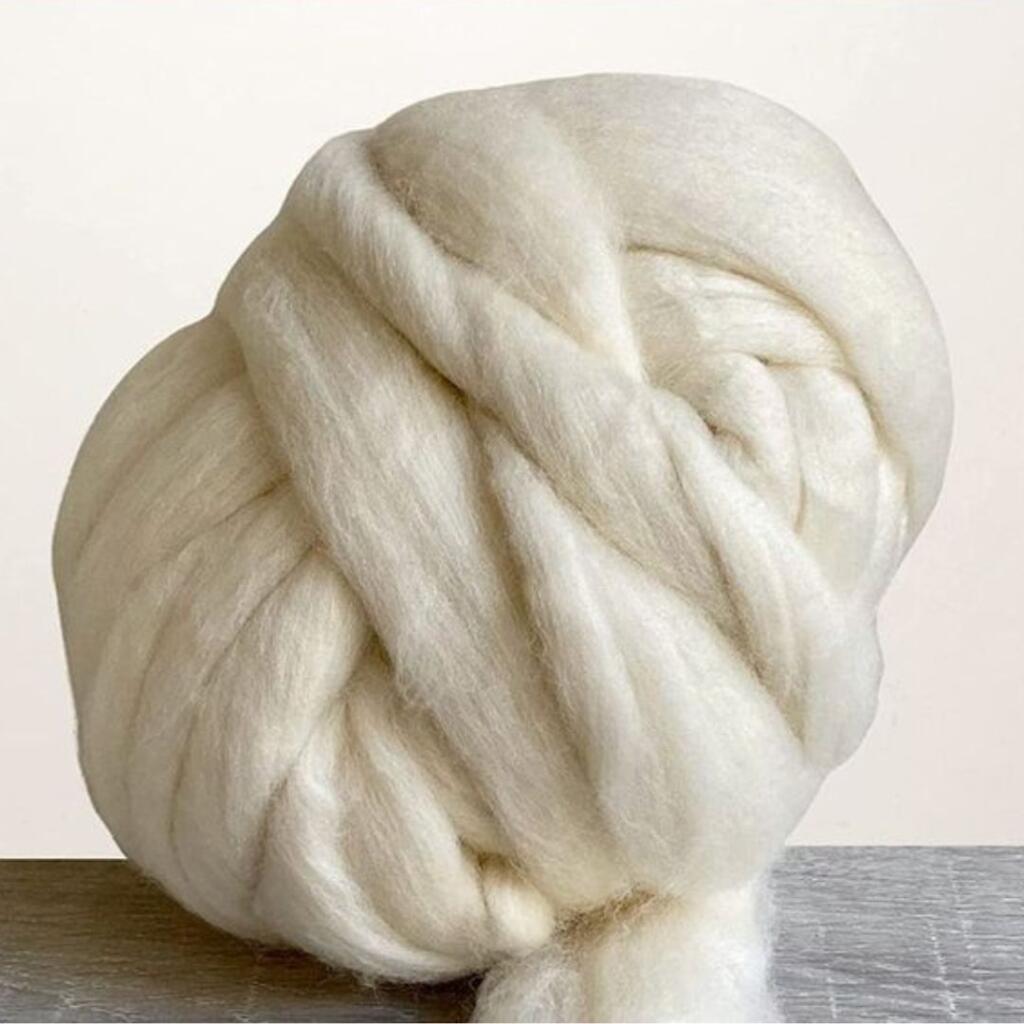

Wool felt can be used as insulation in various applications due to its natural insulating properties. Wool has been historically used for its thermal insulation capabilities, and felted wool is a dense and compact material that further enhances its insulating qualities. Here are some key features and considerations regarding the use of wool felt for insulation:

Thermal Insulation:

Wool fibers have natural insulating properties that help trap air, providing effective thermal insulation. Wool can regulate temperature by absorbing and releasing moisture, making it suitable for different climates.

Moisture Management:

Wool can absorb moisture without feeling damp, helping to manage humidity levels in the environment.

It can absorb up to 30% of its weight in moisture without feeling wet.

Fire Resistance:

Wool is naturally flame-resistant. It has a higher ignition temperature compared to many synthetic materials. It tends to char rather than melt, reducing the risk of spreading fire.

Durability and Longevity:

Wool felt is a durable material that can withstand compression and maintain its insulating properties over time. It is resistant to mold and mildew, contributing to its longevity.

Sustainable Material:

Wool is a renewable and biodegradable material, making it an environmentally friendly choice for insulation. It is sourced from sheep, which can be raised in a sustainable and ethical manner.

Applications:

Wool felt can be used in a variety of applications, including home insulation, industrial insulation, and automotive insulation. It is often used in the construction of clothing, blankets, and other products designed for warmth.

Thickness and Density:

The effectiveness of wool felt as insulation can depend on its thickness and density. Thicker and denser felt generally provides better insulation, but the specific requirements will vary based on the intended use.

When using wool felt for insulation, it’s essential to consider factors such as the specific insulation needs, the environment in which it will be used, and any relevant building or safety codes. Additionally, consulting with experts or professionals in insulation can help ensure that the chosen material meets the necessary standards for the intended application.